At the point when the Coronavirus pandemic dies down, the world will look particularly changed. The stock shock that began in China in February and the interest shock that followed as the worldwide economy shut down uncovered weaknesses in the creation procedures and supply chains of firms pretty much all over. Transitory exchange limitations and deficiencies of drugs, basic clinical supplies, and different items featured their shortcomings. Those turns of events, joined with the U.S.- China exchange war, have set off an ascent in monetary patriotism. As an outcome of this, makers overall will be under more prominent political and cutthroat tensions to build their homegrown creation, develop work in their nations of origin, decrease or even dispose of their reliance on sources that are seen as unsafe, and reconsider their utilization of lean assembling systems that include limiting how much stock held in their worldwide stockpile chains.

However numerous things won’t change. Buyers will keep on needing low costs (particularly in a downturn), and firms will not have the option to charge all the more since they produce in greater expense home business sectors. Contest will guarantee that. Moreover, the strain to work productively and utilize capital and assembling limit efficiently will stay unrelenting.

The test for organizations will be to make their stock chains stronger without debilitating their intensity. To address that difficulty, supervisors ought to initially comprehend their weaknesses and afterward think about various advances — some of which they ought to have taken well before the pandemic struck.

Uncover and Address the Secret Dangers

Current items frequently integrate basic parts or modern materials that require specific innovative abilities to make. It is extremely challenging for a solitary firm to have the expansiveness of capacities important to deliver everything without help from anyone else. Consider the developing gadgets content in current vehicles. Automakers aren’t prepared to make the touchscreen shows in the diversion and route frameworks or the endless microchips that control the motor, directing, and works like power windows and lighting. Another more esoteric model is a gathering of synthetic compounds known as nucleoside phosphoramidites and the related reagents that are utilized for making DNA and RNA groupings. These are fundamental for all organizations creating DNA-or mRNA-based Coronavirus immunizations and DNA-based drug treatments, however a large number of the key forerunner materials come from South Korea and China.

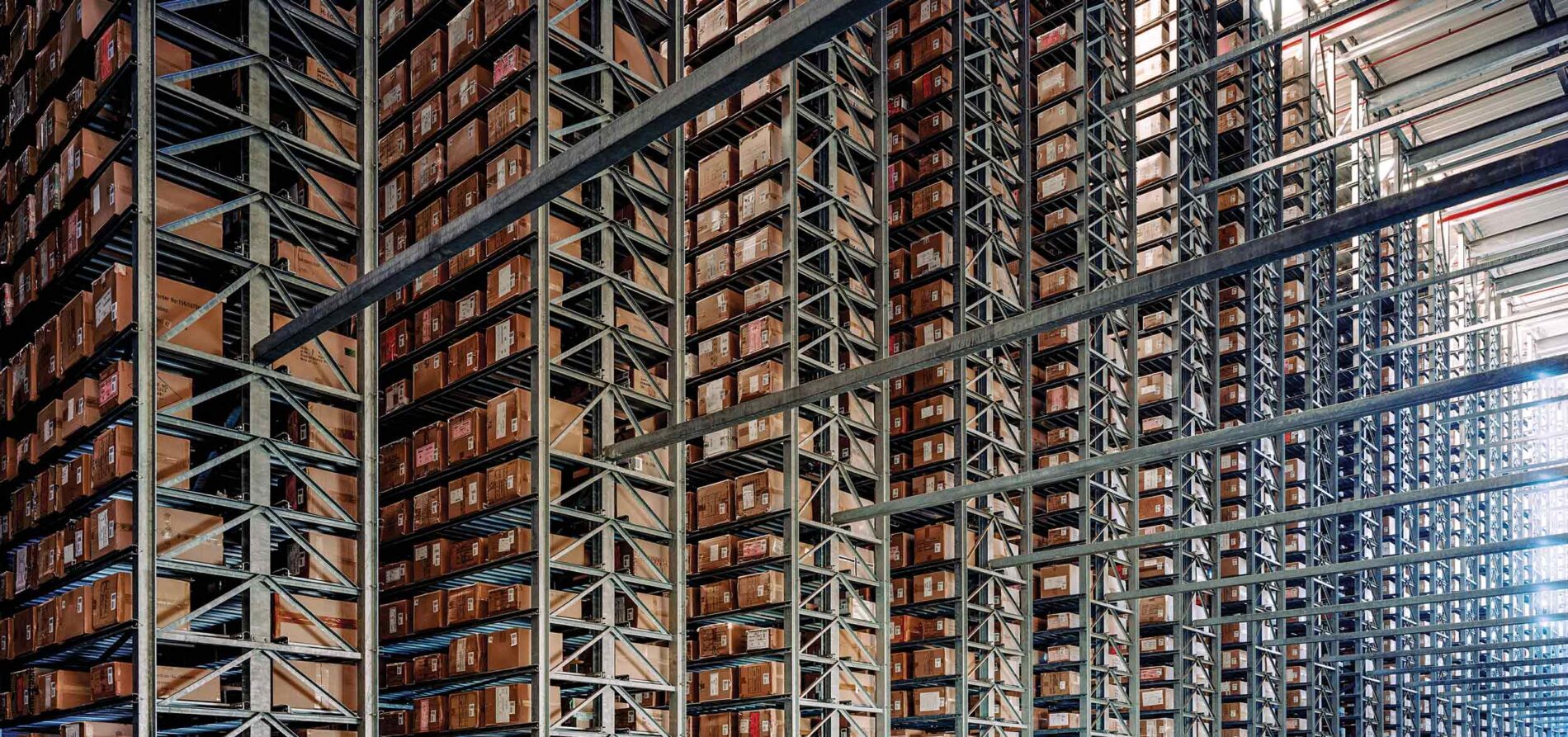

Producers in many businesses have gone to providers and subcontractors who barely center around only one region, and those trained professionals, thus, as a rule need to depend on numerous others. Such a plan offers benefits: You have a great deal of adaptability in what goes into your item, and you’re ready to consolidate the most recent innovation. Be that as it may, you are left powerless when you rely upon a solitary provider some place somewhere down in your organization for an essential part or material. Assuming that provider creates the thing in only one plant or one country, your disturbance chances are significantly higher.

Recognize your weaknesses. Understanding where the dangers lie so your organization can safeguard itself might require a ton of digging. It involves going a long ways past the first and second levels and planning your full store network, including conveyance offices and transportation center points. This is tedious and costly, which makes sense of why most significant firms definitely stand out just on vital direct providers that record for a lot of their consumptions. Yet, an unexpected interruption that stops your business can be considerably more expensive than a profound investigate your store network is.

+ There are no comments

Add yours